Rotary Dryers

Engineering and Manufacturing Dryers for Chemical Process Industries

Rotary Dryers

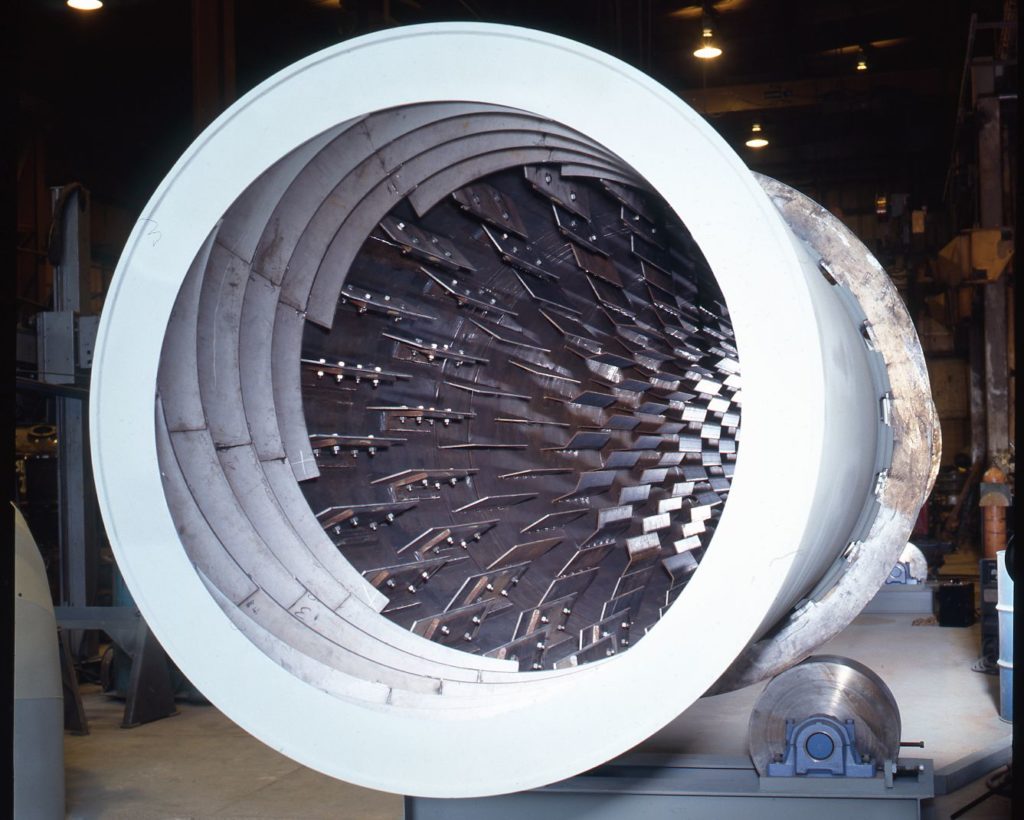

Parallel current operation exposes the wettest material to the hottest air, thus enabling heat-sensitive or sticky material to be dried successfully. The evaporation of water prevents the material from overheating. As the material becomes drier, the air becomes cooler. The hot air at the feed end of the dryer warms the shell and flights, helping to prevent sticking of wet or tacking material to the metal.

Counter-current operation exposes the driest material to the hottest air, thereby producing a product having a very low moisture content, without sacrificing thermal efficiency.

Warm air dryers utilize steam coils to heat ambient air to temperatures as high as 350°F. An exhaust fan, located on either the clean side of a dry dust collector or before a wet scrubber, is used to induce the flow of air though the steam coils, dryer, and pollution control equipment.

Direct heat dryers use an oil, gas or dual-fuel burner housed in a combustion furnace to produce hot air, reaching temperatures of up to 1800°F. The air is drawn through the dryer and pollution control equipment by an exhaust fan.

Rotary coolers, using either ambient or refrigerated air as the cooling medium, are designed much like the rotary dryer and operate in the counter-current mode.